Numerical Simulation and Performance Analysis on Windmill Starting Process of Small Turbojet Engine

YANG Xin-yi(楊欣毅),TIAN Yu(田宇),ZHU Xu-cheng(朱旭程),ZHOU Yuan(周源),LI Guan-jun(李冠軍)

(1.Naval Aeronautical and Astronautical University,Yantai 264001,Shandong,China;2.Detachment 92,Unit No.92941,Huludao 125001,Liaoning,China;3.Naval East China Sea Fleet 19 division,Ningbo 315122,Zhejiang,China)

Introduction

Small turbojet engine,such as missile main engine,is usually started using a windmill.The engine is first driven by using a booster to propel the windmill.Then it is ignited and accelerated into cruise stage.During its starting process,the inlet and components’conditions are changing rapidly,which,in turn,affects the stability of engine and some malfunctions may happen[1].Therefore it is very necessary to study the starting process of missile turbojet engine theoretically.

Some problems exist in the modeling and simulation of starting start process of a missile turbojet engine.In the windmill process before ignition,the pressure ratio of compressor is less than 1.The compressor manufacturer provided only the high rotational speed range of compressor without low rotational speed range.This makes it more difficult to model the windmill state.The compressor can be test to obtain its low speed range on special test beds[2].It can be also acquired by extrapolating the existing characteristics map of high rotational speed.But the extrapolation method needs detailed structure and size data of compressor[3].Windmill process is a complex nonlinear process.A neural network is used to model the engine windmill since it has ability to approximate the nonlinear functions.YU Da-ren[4]used a radial basis function neural network(RBFNN)to model the windmill of missile turbojet engine dynamically on the base of test data on windmill starting.WU Zhi-wen[5]made some improvements on the neural network starting model of engine windmill.He used the relative priori knowledge to transform the input viriable of network and reduce the number of input parameters.As a result,the generalizing ability of the network is enhanced greatly even when the sample data is relatively few.

The starting process model after ignition consists of nonlinear equations.These equations can be solved by Newton-Raphson(N-R)and Broyden method.These methods are simple and widely used.But the iterative methods tend to be easily affected by the initial conditions,and have some convergent problems.In the recent years,some artificial intelligence methods,such as Genetic algorithm and particle swarm optimization(PSO)algorithm,have been applied to solve the engine dynamic model[6-7].And the methods have better performance than the traditional iteration methods.

When the oil control of engine is definite,the ignition time becomes very important to windmill starting.Different ignition time results in different starting performance.The ignition time is usually determined by tests.The effects of ignition time on stability margin of compressor,temperature of combustion chamber and starting time has never been analyzed theoretically.

In this paper,the start process of a missile turbojet engine is divided into two parts:windmill process before ignition and acceleration process after ignition.The windmill process before ignition is simulated by neural networks,and the nonlinear functions of acceleration process after ignition are solved by PSO algorithm.The whole rotational speed range of compressor is obtained using moving least squares(MLS)on the basis of test data.The effect of ignition time on engine starting performance is obtained using the proposed method.

1 Modeling of Engine Starting Process

1.1 Modeling of Windmill Process

The engine is not ignited during the windmill process.Therefore not all the parameters need to be solved.Attention is paid on the parameters such as rotational speed,compressor outlet pressure,thrust and air flow,which have great influence on engine performance.

The turbojet engine is driven into windmill process with the aid of the propulsion of missile booster.So,the inlet has the same Mach number as the missile.The rotational speed during windmill process can be calculated from the Mach number curve of missile[8]and the characteristic curve of engine windmill.The focus now is to obtain the parameters of compressor outlet pressure,thrust and air flow.

As windmill start test is difficult to execute,the acquired test data are just a few curves of compressor outlet pressure and rotational speed.In the case,the generality ability of traditional neural network tends to be weak.In order to improve the generality ability of network,some relative priori knowledge,such as the relation between residual power and acceleration,is used to transform the network input parameters.

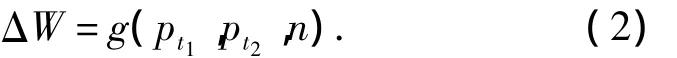

A mathematical model of windmill start is established using the neural network.If the rotor inertia is considered and the engine thermal inertia is ignored,the relationship between rotational speednand the inlet pressurept1and outlet pressurept2of compressor is given by

whereJ,engine rotor inertia,is a constant.ΔWis the acceleration moment of engine:

The network which needs training is as follows

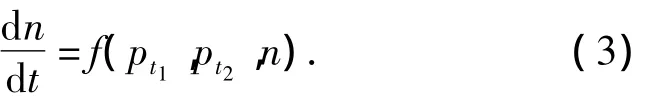

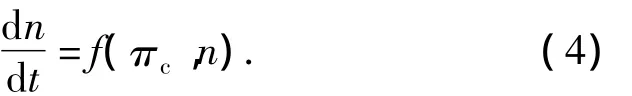

It can be seen from Eq.(3)that the input parameters of network arept1,nandpt2,and the output parameters is dn/dt.The input variables are recombined using the priori knowledge.Ifpt1andpt2can be replaced by pressure ratio,then the network becomes

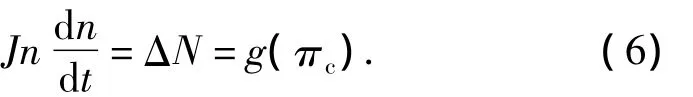

Rotational speed is strongly depend on pressure ratio,thus the input parameters can be transferred farther.The rotor is accelerated by the residual power ΔN:

It can be seen from the compressor characteristic map that the unit power of compressor is dependent onπcand independent ofn.Thus the rotational speed only affects the left part of Eq.(5),and the right part of Eq.(5)is the function ofπc.Then Eq.(5)is written as

As a result Eq.(4)can be rewritten as

Now the network output is the differential coefficient ofn2,we can easily getnfromn2by its integral and extraction.Asnis known,the input and output of Eq.(7)are exchanged to obtain the relation betweenπcandn:

When the network is trained,the input sample is d(n2)/dt=2n(dn/dt),the rotational speed curves need to be differentiated smoothly,and dn/dt is replaced with Δn/Δt.

In this paper the RBF network is used to model the windmill starting.Because the priori knowledge is used,the network has better generality ability.The network training is performed by Matlab toolbox.

The thrust and air flow during the windmill process are calculated by the method presented in Ref.[9-10].

1.2 Modeling of Acceleration After Ignition

1.2.1 Dynamic Model of Acceleration

In a short time after ignition,the flame flows into the turbine rapidly and drives it to rotate.The turbine output power rises greatly and drives the compressor to work.Meanwhile the operating temperature rise of turbine decreases the flame density and the air flow.While the pneumatic thermal parameters change faster than the rotational speed,resulting in the sudden upwards of engine working line on the compressor characteristics map.The working line goes upwards from a point which pressure ratio is less than 1 to a new point which pressure ratio is bigger than 1,while the rotational speed keeps unchanged.

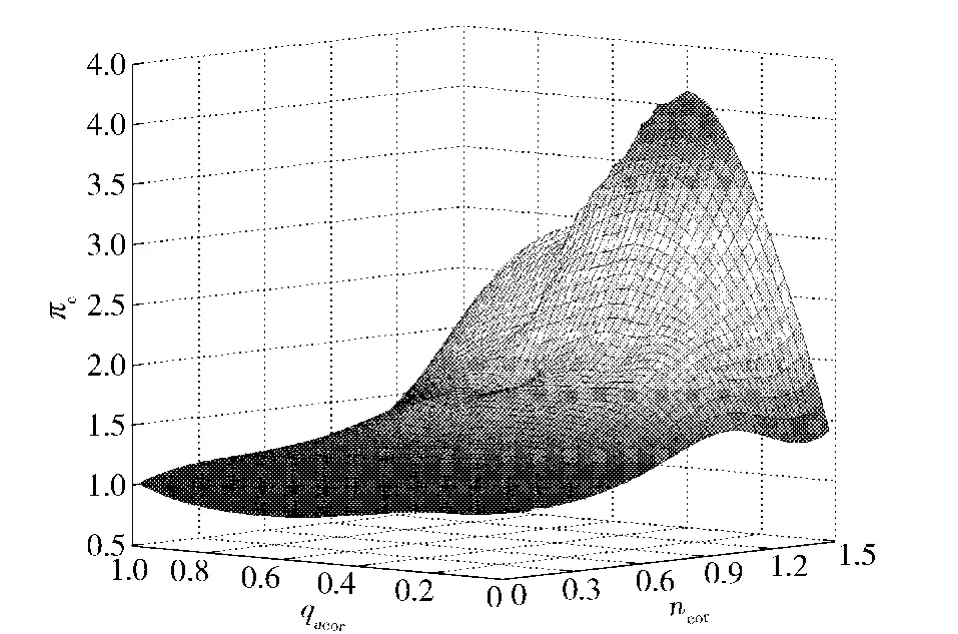

In order to get the whole working line,the acceleration after ignition needs to be modeled.The dynamic model of acceleration process consists of the following three equations:

wherePEXTis the power extracting value,(qmgcor)caland(qmgcor)figare the calculated air flow of turbine inlet and the value read from the turbine characteristics map,respectively,pt4andp't4are the turbine outlet pressure calculated by different ways,pt4is calculated from the component modules before nozzle,andp't4is calculated from nozzle module.

1.2.2 Extension of Compressor Characteristics Map

The compressor characteristics map on the whole range of rotational speed is necessary for the simulation of engine starting.While the known map has only the characteristics data of high speed,it is required to extend the map to low rotational speed.

The test data is necessary to obtain a map of whole rotational speed range.And some parameters of compressor can be extracted from test data.These data and the data in the known map are used to obtain the map of the whole speed range by a surface fitting technique[11].

The compressor parameters can be extracted from test data which is obtained on ground test bed or altitude test bed.Below are the equations used for parameter extraction.

wherencoris the corrected rotational speed,qacoris the corrected air flow,ηcis the compressor’s efficiency,Tt1,pt1andp1are the total temperature,total pressure and pressure of compressor inlet,andTt2,pt2are the total temperature and total pressure of compressor outlet.

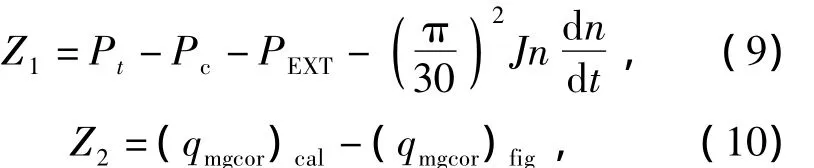

The extracted pressure ratios and the corrected air flows at 10%,30% and 50% corrected rotational speeds are listed in Tab.1.

Tab.1 Characteristics data calculated from test data

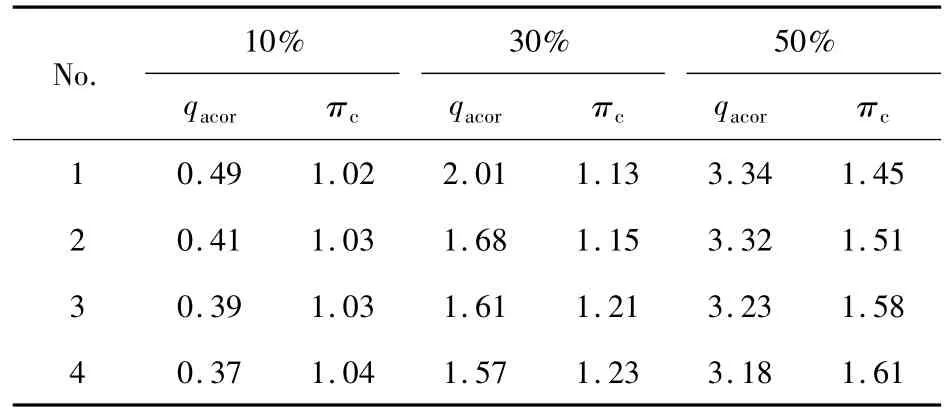

It is convenient to transfer the planar compressor characteristics map into a spatial surface.The characteristic data points are used to fit a surface.The distribution of test data points is shown in Fig.1.

Fig.1 Distribution of domain nodes at space

The traditional least squares(LS)method is used difficult to fit a surface based on these points because the distribution of data points at space is complex.In this paper a moving least squares(MLS)method is used to approximate the compressor characteristics surface.

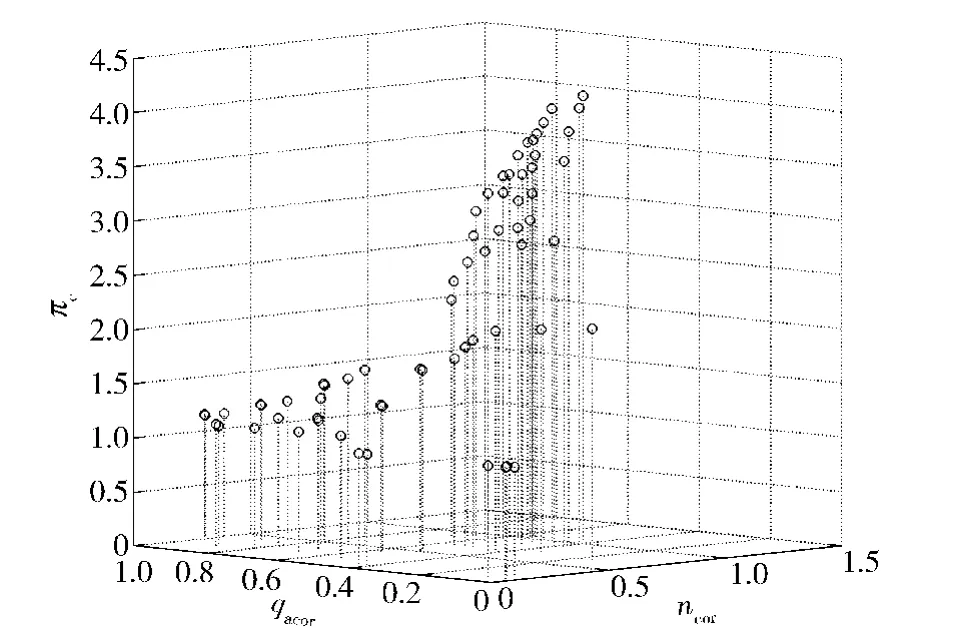

MLS is different from traditional LS.It consists of a coefficient vectora(x)and a base vectorp(x).The concept of compact support is introduced.This means thata(x)is a function of coordinatexand is constant only in the interpolation domain of base points.MLS makes it easier to approximate the compressor characteristics surface than the traditional LS.The approximated surface is illustrated in Fig.2.

1.2.3 Solution of Model Nonlinear Equations

Fig.2 Fit surface of compressor pressure ratio

The dynamic model of engine starting is a nonlinear equation set.These equations are usually solved by some numeric iterate method like Newton-Raphson(N-R)method.But these methods are very sensitive to the initial values and need to calculate the differential coefficients of the equations at every iterative timestep.These characteristics often lead to the divergence of the model solution.

Recently particle swarm optimization(PSO)algorithm has shown its advantage in the engine model solution.PSO algorithm is a bionic optimization algorithm firstly put forward by Kennedy and Eberhart[12].In PSO algorithm,a population of particles is initialized firstly,and then the particles are iterated to get the optimum solution.When iterated,a particle updates itself by two“best solutions”.One is the best solution obtained by the particle itself(called personal best,pbest.),the other is the best solution obtained by the whole population(called global best,gbest).All particles are set into aD-dimension solution space and the number of particles isn.Theith particle flies in the solution space with a certain velocity.And this velocity is adjusted dynamically with the paricle’s own experience and other particles’experience.The position of theith particle isXi=(xi1,xi2,…,xiD)and its personal best(pbest)isPi=(pi1,pi2,…,piD).The global best(gbest)of the whole population isPg=(pg1,pg2,…,pgD).The velocity of thei-th particle isVi=(vi1,vi2,..,viD).

For any particle,itsdth dimensional(1≤d≤D)velocity and position are calculated as the follow

wherei=1,2,…,n;d=1,2,…,D;wis the inertia weight;which is often used as a parameter to control exploration in the search space.c1andc2are the acceleration constants(usually setc1=c2=2),and particles’maximum velocity is limited by.When PSO algorithm is applied to solve engine nonlinear equations,the particles are equation’s candidate solutions,gbest is the best solution until current iteration and the fitness function isZ=F(X).

As PSO is insensitive to initial condition values,the algorithm has better convergence performance than the traditional iteration methods when the engine model is solved.In this paper the equations of engine starting model are solved using PSO algorithm.

2 Simulation of Engine Starting Process

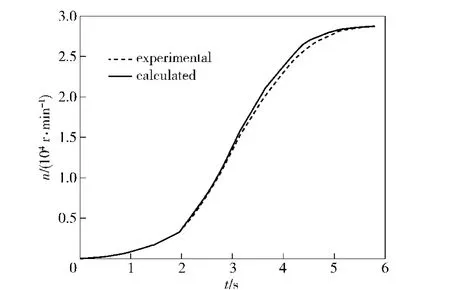

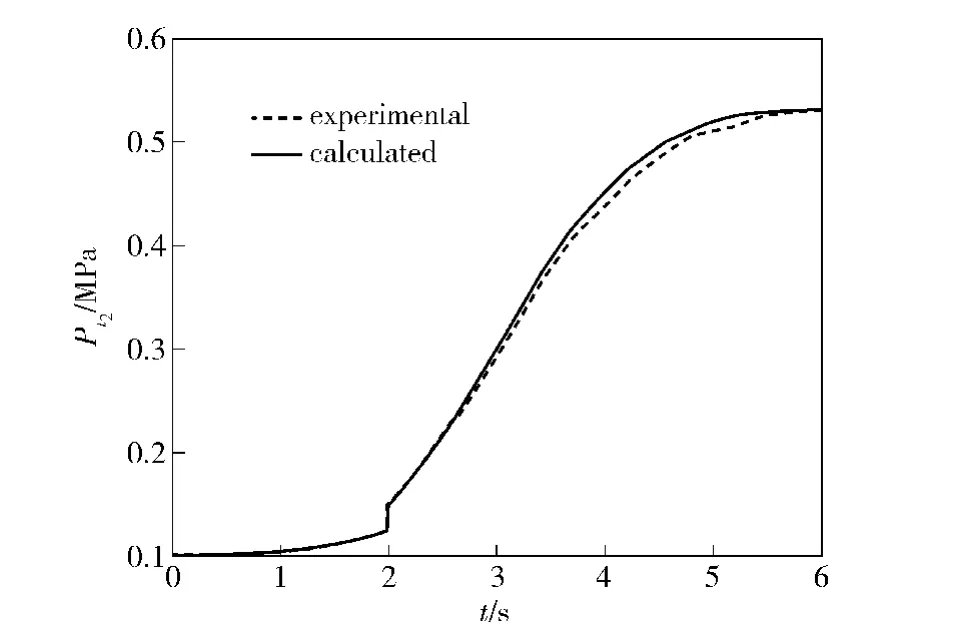

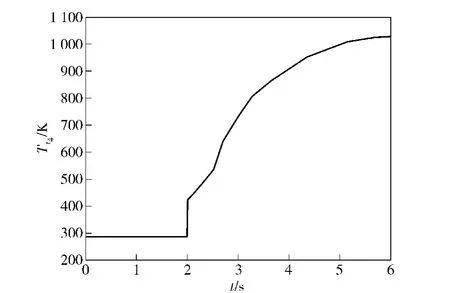

The whole engine starting process is simulated by the methods mentioned above.The simulated windmill starting time is the time when the rotor begins to rotate.The engine ignites 1.99 s after the windmill starts,which is also the starting time of acceleration process.The engine start model is solved by PSO.Some simulated parameters as the rotational speed,the total pressure and total temperature of combustor outlet are shown in Fig.3 to 5.As only a few parameters are measured remotely,the measured parameters which can be compared with the simulated ones are rotational speed and compressor outlet pressure.

Fig.3 Rotor speed-time curve during starting process

It can be seen from Fig.3 that the simulated rotational speed curve is very close to the test curve.The maximum error is 3.6%.From Fig.4 we can know that the simulated total pressure of compressor outlet is also close to the test curve,and the maximum error is 5.2%.When the engine is ignited,the outlet pressure rises abruptly.It can be seen from Fig.5 that the temperature of combustor rises suddenly,and it rises rapidly as the oil is supplied to the combustion chamber.

Fig.4 Pressure curve of compressor outlet during starting process

Fig.5 Temperature curve of combustor outlet during starting process

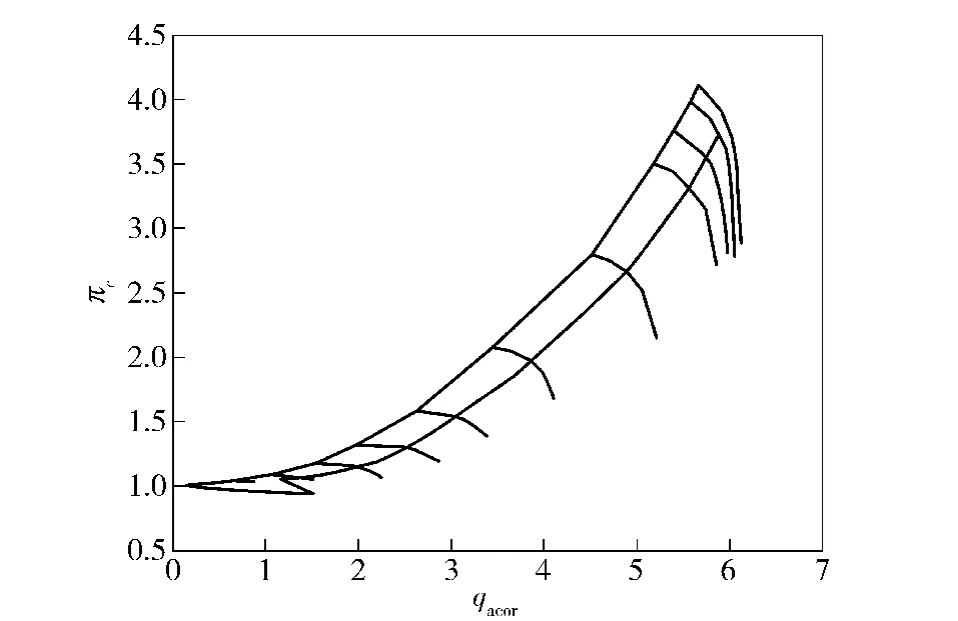

Fig.6 is the simulated working line of engine.It can be seen from Fig.6 that the compressor pressure ratio is less than 1 during windmill stage as the compressor is driven by the inlet air flow.After ignition,the working line turns upwards along the same rotational speed line as the thermal parameters change rapidly while the rotational speed keeps stable.Afterwards,the rotational speed rises with increase in oil supply.It can be seen from Fig.6 that the surge margin reaches the least during ignition.After ignition,the working line keeps a certain surge margin.For the engine starting process,the ignition time is the most important.When an ignition time is selected,the surge margin of compressor must be considered and kept in a safe range.For the simulated engine starting,the ignition(rotational speed is 4 951 r/min)surge margin is 15.98%,which meets the safety requirement of engine.

Fig.6 Operation line on compressor map during starting process

The starting time of missile turbojet engine is defined as the time from 0 to 90%maximum rotational speeds.By this definition,the starting time of engine is 4.975 s.During starting process,the combustor temperature suddenly rises after ignition,and the highest temperature reaches 1032.6 K,which is lower than the restricted temperature of combustor outlet.

3 Effect of Ignition Time on Starting Performance

The main factors affecting the engine starting performance include oil control law and ignition time.Under the condition of a fixed oil control law,the ignition is a key to the starting performance.For the missile turbojet engine under study,its ignition time is determined by test.Though the present ignition time guarantees the successful starting of engine,few researches have been done on the effect of ignition time on engine starting performance.In this paper,the effect is studied theoretically in detail.

3.1 Effect of Ignition Time on Acceleration

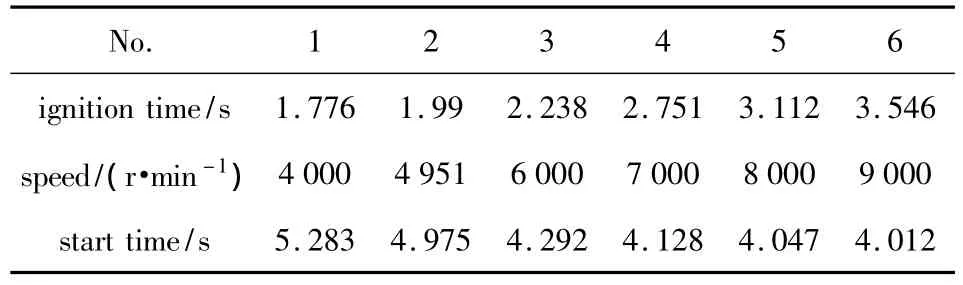

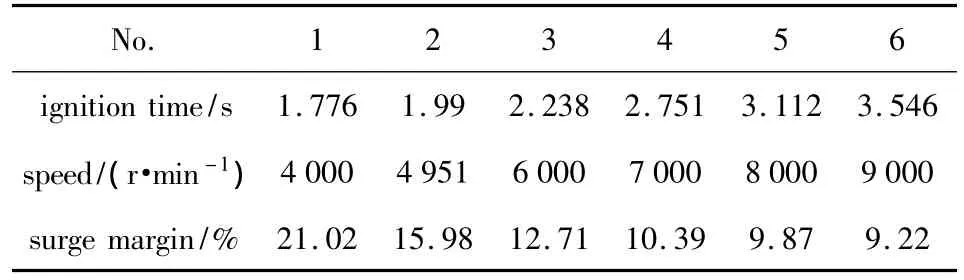

In order to investigate the effect of ignition time on acceleration performance,six different ignition times are selected(No.1 -6).Starting time and rotational speed at six ignition times are listed in Tab.2.

Tab.2 Effect of ignition time on starting time

To compare the difference between the starting processes,the rotational speed curves under different condition are listed in a three dimensional space with three coordinates:time,ignition time,and rotational speed.As shown in Fig.7,the starting process of engine is different at a different ignition time.The later the ignition time is,the shorter the engine starting time is.As shown in Tab.2,when the engine is ignited at 3.546 s,the starting time is 19.36%shorter than the normal starting time.

Fig.7 Rotational speed lines at different ignition times

3.2 Effect of Ignition Time on Compressor Surge Margin

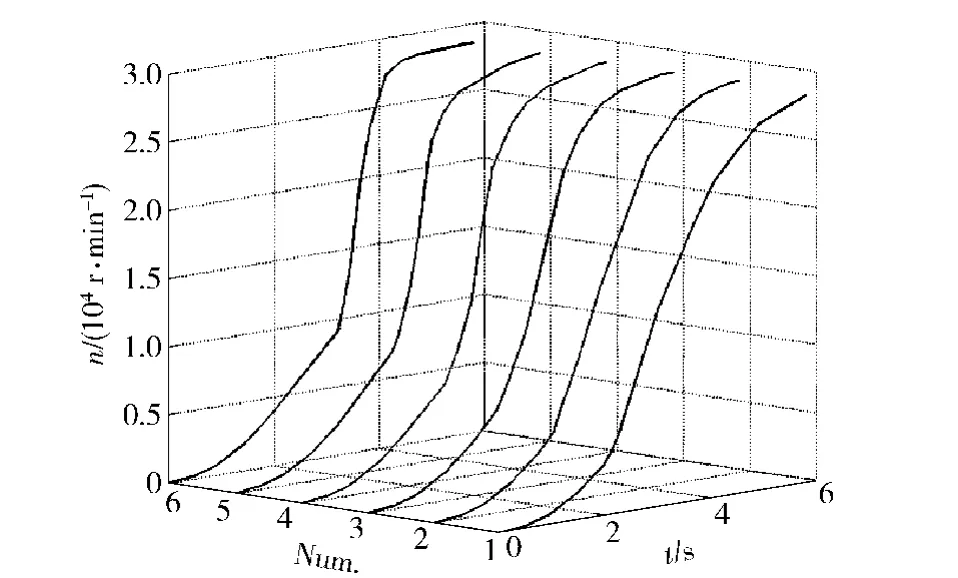

For the selection of ignition time,only the starting time should be not considered,but the effect of ignition time on the stability of compressor during starting process is also considered.As described in Section 3.1,the surge margins of six ignition times are calculated and listed in Tab.3,and the six working lines are listed in Fig.8 with its three coordinates,including air flow rate,ignition time,and pressure ratio.

Form Fig.8 we know that the upward step of working lines become more evident with the later ignition times,at the same time,the surge margins decrease.From Tab.3 we know that the surge margin is only 9.22%,which is 42.3% less than the normal one when it is ignited at 3.546 s.

Fig.8 Working lines vs.ignition times

Tab.3 Effect of ignition time on surge margin

3.3 Effect of Ignition Time on Combustor Outlet Temperature

Usually the temperature of combustor outlet is restricted during starting process.The calculated result shows that the temperature of combustor outlet suddenly rises after ignition.The later the ignition time is,the greater the rise in temperature is.But the temperature curves of different ignition times all tend to 1 032 K which is less than the restricted temperature(1 143 K).It is concluded that the ignition time has a little influence on the temperature of combustor outlet,and its temperature won’t exceed the restricted value.

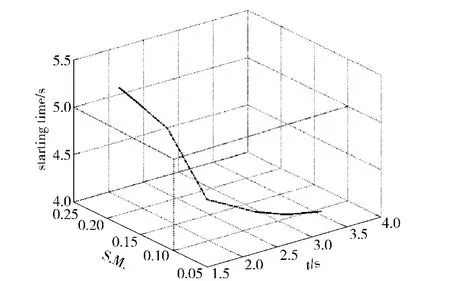

In general,the ignition time does have influence on engine starting performance.The later the ignition time is,the shorter the start time is,while the surge margin decreases.The ignition time has little influence on the temperature of combustor outlet.As a result,the determination of ignition time should consider the starting time and surge margin synchronously.The relationship between ignition time and starting performance can be given by a curve shown in Fig.9.This curve is helpful for determination of ignition time.For example,if the surge margin restriction is 10%and the starting time is no more than 5 s,then the ignition time envelop is the dashed line part of the curve.This part corresponds to 1.91-3.02 s.If the ignition time is within this part,the engine has a short acceleration time and provides the surge margin.

Fig.9 Acceleration performance vs.ignition times

4 Conclusion

In this paper,the starting process of a missile turbojet engine is simulated.The starting process of engine is divided into two parts:windmill and acceleration after ignition.The former is simulated by neural networks and the later nonlinear equations are solved using the particle swarm optimization algorithm.The optimization algorithm has greater convergence performance than the traditional iteration methods and improves the modeling accuracy ofengine starting process.Agreement between simulated results and test data suggests that the proposed mathematical method is very useful for the simulation of missile turbojet windmill starting.The effect of ignition time on engine starting performance is obtained by modeling the starting process at six different ignition times.This provides a research method and useful tool for the analysis of engine performance and the determination of ignition time.

[1]YU Jun,YU Shou-zhi.Starting and accelerating model of missile turbojet engine in flight test[J].Journal of Propulsion Technology,2001,22(6):454 -457.(in Chinese)

[2]ZHAO Qi-shou.Calculation of wind mill characteristics of turbojet engines[J].ASME Jounal of Engineering for Power,1981,103(1):1 -12.

[3]Chappell M A.Approach to modeling continuous turbine engine operation from startup to shutdown[J].Journal of Propulsion and Power,1993,9(3):466 -471.

[4]YU Da-ren,GUO Yu-feng,NIU Jun.Turbojet modeling in windmill based on radial basis function net works[J].Journal of Propulsion Technology,2001,22(3):183 -186.(in Chinese)

[5]WU Zhi-wen,YU Da-ren,NIU Jun.Turbojet modeling and simulation based on ANFIS[J].Journal of Propulsion Technology,2005,26(2):162 -166.(in Chinese)

[6]SU San-mai.Research on Genetic algorithm and the application in aeroengine nonlinear model[D].Xi’an:Northwestern Ploytechnical University,2002.(in Chinese)

[7]YANG Xin-yi,PANG Shan.Theaeroengine model based on improved PSO algorithm[C]∥The 2nd International Symposium on Jet Propulsion and Power Engineering,Beijing:Beihang University,2008:585-588.

[8]HUANG Jia-hua,FENG Guo-tai,NIU Jun,et al.Effect of turbine efficiency changing on turbo engine’s accelerating characteristic under closed loop control model[J].Journal of Propulsion Technology,2003,24(4):368 -372.(in Chinese)

[9]WANG Zhan-xue,LIU Zeng-wen.The calculation of windmill characteristics of a gas turbine engine[J].Journal of Gas Turbine Experiment and Research,2006,19(4):8-10.(in Chinese)

[10]LU Yao,ZHANG Li-tang,YU Shou-zhi.Calculation of air mass flow in air breathing engine test[J].Journal of Propulsion Technology,2001,22(6):489 - 492.(in Chinese)

[11]YANG Xin-yi,SHEN Wei,LIU Hai-feng,et al.Compressor characteristics generation method using moving least square[J].Journal of Aerospace Power,2009,24(8):1741 -1746.(in Chinese)

[12]Kennedy J,Eberhart R.Particle swarm optimization[C]∥Proceedings of IEEE International Conference on Neural Networks,Piscataway:IEEE Service Center,1995,4:1942-1948.

- Defence Technology的其它文章

- Application of Adaptive Backstepping Sliding Mode Control in Alternative Current Servo System of Rocket Launcher

- Optimization Design of Double-parameter Shift Schedule of Tracked Vehicle with Hydrodynamic-mechanical Transmission

- A New Single DIFAR Sonobuoy Target Location Algorithm

- Waveguide Invariant and Passive Ranging Using Double Element

- Reliability Sensitivity Analysis for Location Scale Family

- Research on Estimation of Time Delay Difference in Passive Locating for Impulse Signal