響應曲面法優化微波輔助提取白豆蔻揮發油的工藝研究

李 超,商學兵,王乃馨,高獻禮,鄭 義

(1.徐州工程學院食品工程學院,江蘇 徐州 221008;2.江南大學生物工程學院,江蘇 無錫 214122)

響應曲面法優化微波輔助提取白豆蔻揮發油的工藝研究

李 超1,商學兵1,王乃馨1,高獻禮2,鄭 義1

(1.徐州工程學院食品工程學院,江蘇 徐州 221008;2.江南大學生物工程學院,江蘇 無錫 214122)

在單因素試驗基礎上,采用Box-Behnken設計對白豆蔻揮發油微波輔助提取工藝中的液料比、微波時間和微波功率3因素的最優化組合進行定量研究,建立并分析各因素與得率關系的數學模型。結果表明,最佳的工藝條件為液料比10:1(mL/g),微波時間153s和微波功率322W。經驗證實驗,在此條件下得率為2.67%,與理論計算值2.64%基本一致。說明回歸模型能較好地預測白豆蔻揮發油的提取得率。

微波輔助提取;白豆蔻;揮發油;響應曲面法

Fructus Amomi Rotundus (Baidoukou in Chinese), the dried fruits of Amomum kravanh Pirre ex Grgnep. or Amomum compactum Soland ex Maton, is one of the most popular traditional Chinese medicines and officially listed in the Chinese Pharmacopoeia[1]. It has been widely used for eliminating dampness, strengthening spleen, warming stomach, preventing vomiting and curing internal obstruction caused by colddamp, epigastric, abdominal or turgid psychroalgia and poor appetite[1]. Microwave-assisted extraction (MAE) has received an increasing attention as an alternative technique for extracting active ingredients from plants because it may decrease the extraction time and the required amount of solvent, and produce products with high quality and low cost[2-12]. Compared with the conventional extraction techniques, the apparatus of MAE is simpler and cheaper, and the MAE is suitable for processing wider varieties of raw materials with less limitation to the polarity of solvent[13]. At the same time, only a few minutes are required in MAE, while the conventional extraction techniques usually takes several hours. So far, there was no report concerning the MAE of volatile oil from Fructus Amomi Rotundus. The aim of this study was to optimize the MAE of volatile oil from Fructus Amomi Rotundus.

1Materials and Methods

1.1Materials and chemicals

Fructus Amomi Rotundus was purchased from Anhui Bozhou Sanyitang Medicine Manufacture Co.,Ltd. The Fructus Amomi Rotundus was carefully cleaned by hand to remove the foreign materials such as stones and small stalks, ground to a fine and homogeneous powder using mullers, and then sieved through a 40 mesh sieve. The crushed powder was kept in a vacuum dryer until use.

All of the solvents of n-hexzane, petroleum ether, ethyl acetate, ethyl ether and anhydrous sodium sulfate used in this experiments were of analytical grade and purchased from Sinopharm Chemical Reagent Co., Ltd (Shanghai, China).

1.2Methods

1.2.1Microwave-assisted extraction

A microwave-assisted extraction apparatus (CW-2000, 2450 MHz, Xintuo Microwave Instrument Co., Ltd.) equipped with a programmable heating power from 0 to 800 W with 0.1% increment was used. The crushed Fructus Amomi Rotundus powder was weighed exactly (20.0 g) and placed in a 500 mL quartz extraction cell equipped with reflux system. All of the experiments were performed under a set of microwave power (between 100 W and 500 W) for a certain period of time (between 90 s and 240 s) in a set of solvent volume (between 120 mL and 280 mL). When the extraction completed, 5 g of anhydrous sodium sulfate was added into the extractive to remove water and the extractive was filtrated through a qualitative filter to remove residues, and then the extractive was collected and concentrated with a rotary evaporator (Senco R201L, Shanghai Shen-Sheng Scientific and Technology Company, China) at 50 ℃ to acquire the volatile oil. The concentrate was further dried in a vacuum dryer to remove the residual solvent. In this study, all of the experiments were performed in triplicates, and the results reported here were the means of the three trials.

1.2.2Experimental design and statistical analysis

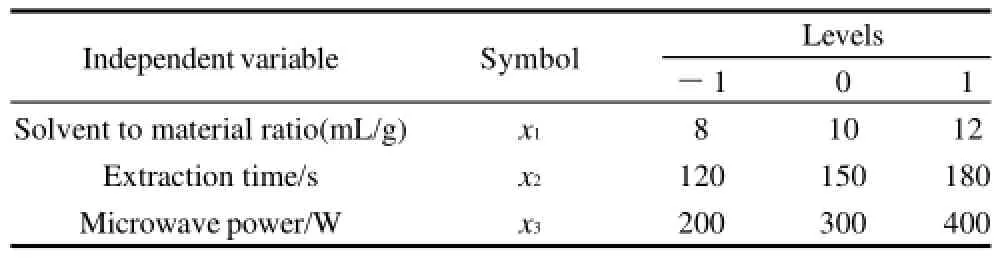

The effects of some factors, such as different extractants, solvent to material ratio, extraction time and microwave power, on the extraction yield (EY) of volatile oil were firstly considered, and then on the basis of results above, the Box-Behnken design was applied to optimize the extraction process of volatile oil from Fructus Amomi Rotundus. The effects of independent variables x1(solvent to material ratio, mL/g), x2(extraction time, s) and x3(microwave power, W) at three levels in the extraction process was shown in Table 1.

Table 1 Codes and levels of factors used in Box-Behnken design

The generalized second-order polynomial model used in the response surface analysis was as follows:

Where EY is the predicted response value, β0, βi, βijand βiiare the regression coefficients for intercept, linear, interaction and quadratic terms, respectively, and xiand xjare the independent variables. The factor number (n) here is 3 in this experiment. The software Design-Expert V 7.0.0 Trial (State-Ease, Inc., Minneapolis MN, USA) was used to generate response surfaces and contour plots while holding a variable constant in the second-order polynomial model. And according to the Box-Behnken Design, 15 tests are required for the regression and fit of regression coefficients in the equation above.

1.2.3Extraction yield determination

Fructus Amomi Rotundus was calculated using the following formula:

Where meis the mass of volatile oil extracted in the solution (g) and mtis the mass of Fructus Amomi Rotundus (g).

2Results and Discussion

2.1Single factor experiments

2.1.1Effects of different solvents

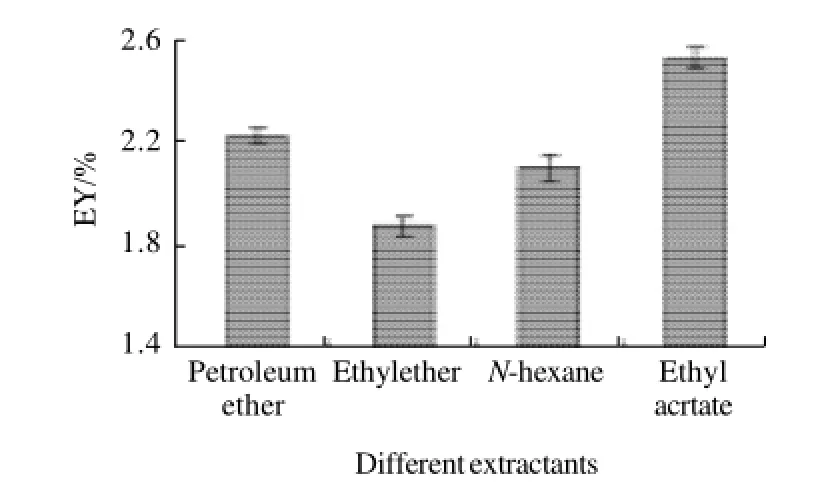

Fig.1 Effects of different extractants on EY

Effects of petroleum ether, ethyl ether, n-hexane and ethyl acetate on the extraction yield of volatile oil from Fruc-tus Amomi Rotundus was shown in Fig.1. Significant differences in the extraction yield using different extractants were observed, ethyl acetate possesses the highest extraction yield (2.54%), whereas ethyl ether possesses the lowest extraction yield (1.88%). Thus, ethyl acetate was used as the optimal extractant in the following investigation.

2.1.2Effects of solvent to material ratio

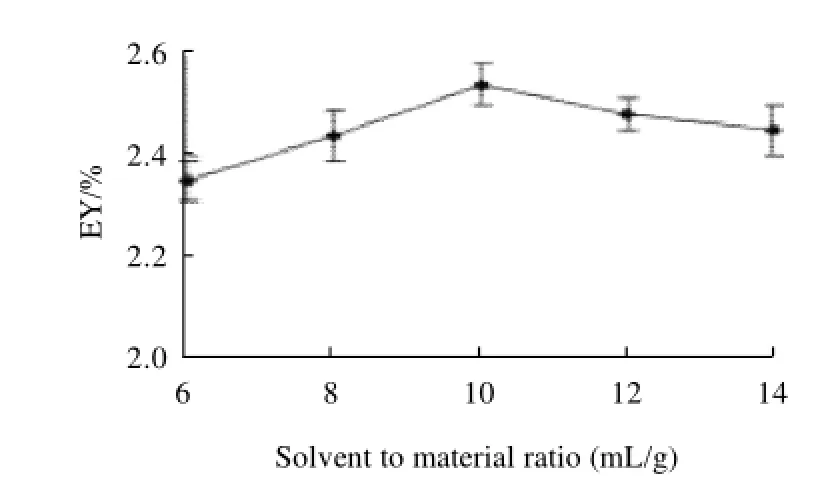

Fig.2 Effects of solvent to material ratio on EY

Effects of solvent to material ratio on the extraction yield was shown in Fig.2. The extraction yield increased significantly when the solvent to material ratio was in 6 to 10 mL/g, but it decreased significantly when solvent to material ratio was higher than 10 mL/g. Thus, 10 mL/g was selected as the optimal solvent to material ratio in the following investigation.

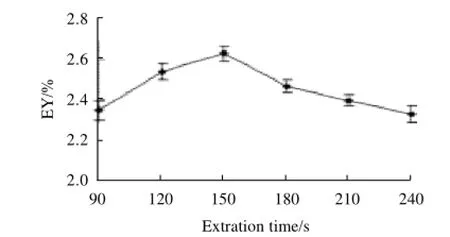

2.1.3Effects of extraction time

Fig.3 Effects of extraction time on EY

The extraction yield increased continuously with the prolonging of extraction time was shown in Fig.3 in the earlier stage. Optimal extraction time was 150 s in respect to the maximum extraction yield of 2.63%. If prolonging the extraction time again, the extraction yield decreased significantly. This was because too longer exposure in microwave irradiation, resulting in the decomposition of certain active constituents. Thus, 150 s was selected as the suitable extraction time in the following investigation.

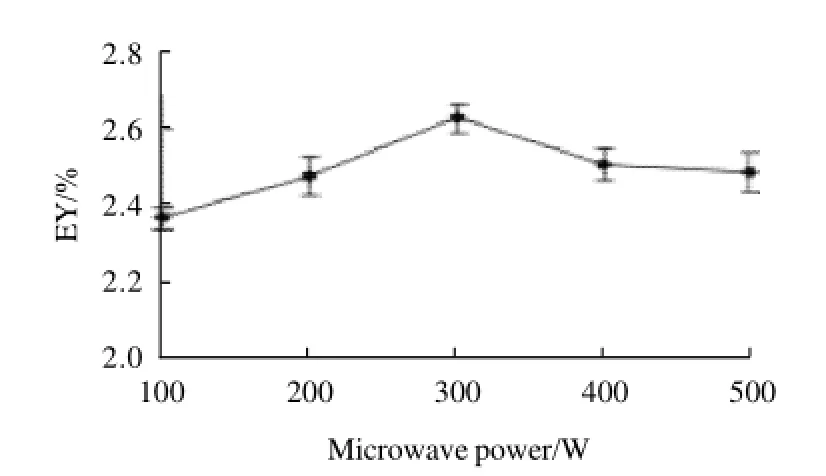

2.1.4Effects of microwave power

Effects of microwave power on the extraction yield was shown in Fig.4. The extraction yield increased significantly when microwave power increased from 100 to 300 W, but it decreased significantly when the microwave power was further increased from 300 to 500 W. Thus, 300 W was the optimal microwave power for the volatile oil extraction.

Fig.4 Effects of microwave power on EY

2.2Optimization of MAE experiments

2.2.1Fitting the model

As shown in Table 2, a regression analysis was carried out to fit mathematical model to the experimental data aiming at an optimal region for the responses studied.

Table 2 The experiment results of Box-Behnken

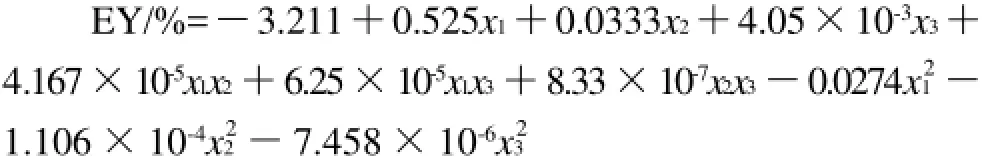

The predicted model can be described by the following equation in terms of actual values:

The significance of each coefficient was determined using the F-test and P-value in Table 3. The corresponding variables would be more significant if the F-value becomes greater and the P-value becomes smaller. It can be seen that the variables with the larger effect were the linear terms ofextraction time (x2), microwave power (x3) and the quadratic terms of solvent to material ratio (x12), extraction time (x22) and microwave power (x32). As shown in Table 3, the model was of great significance (P=0.0016<0.01), the Lack of Fit (P= 0.2648>0.05) was not significant, the adjusted coefficient of determination (R2Adj) of the predicted model was 0.9325 and the Adeq Precision was 12.783 (much larger than 4). Thus, the predicted model seemed to represent the observed values. And the response was sufficiently explained by the model.

Table 3 ANOVA results of quadratic regression model for response surface analysis

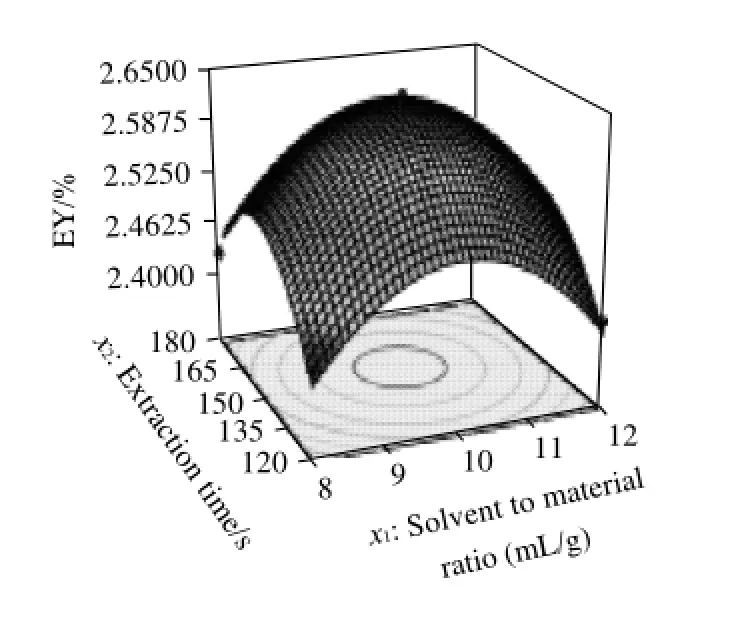

2.2.2Analysis of response surface

The regression model allowed the prediction of the effects of the three factors on the extraction yield of volatile oil from Fructus Amomi Rotundus. The relationship between independent and dependent variables was illustrated in tridimensional representation of the response surface and twodimensional contour plots generated by the model for the volatile oil extraction (Figs.5-7).

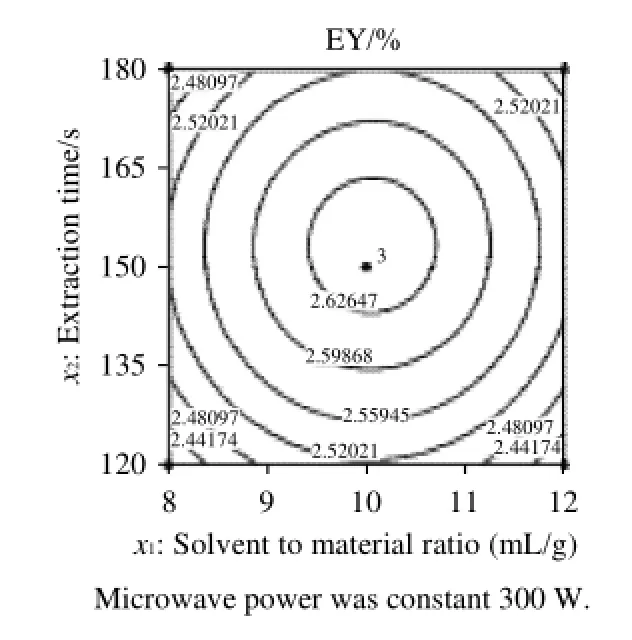

Fig.5 Response surface and contour of effects of solvent to material ratio and extraction time on EY

Fig.6 Response surface and contour of effects of solvent to material ratio and microwave power on EY

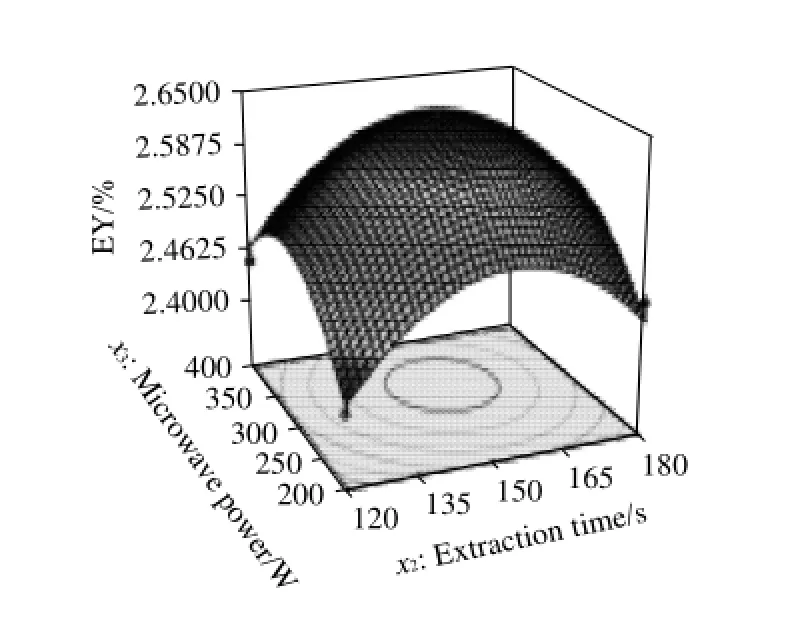

Fig.7 Response surface and contour of effects of extraction time and microwave power on EY

Fig.5 depicts response surface and contour plots of the effects of solvent to material ratio and extraction time on the extraction yield. Solvent to material ratio only had a significant linear effect on the response value, however, the extraction time demonstrated a linear and quadratic effect on the response value approximately. The effect of extraction time on the surface value displayed a linear effect when extraction time was ranged from 120 to 135 s and from 165 to 180 s, while it showed a quadratic variation when extraction time ranged from 135 to 165 s, which accorded with the analysis of Table 3. Fig.6 depicted the effects of solvent to material ratio and microwave power. The microwave power had a significant linear and quadratic effect on the response value. The effects of extraction time and microwave power was depicted in Fig.7, a quadratic effect for both extraction time and microwave power on the response value could be observed. Meanwhile, interaction between three factors could also be observed in Figs.5-7.

2.2.3Verification experiments

By computation, the optimal conditions to obtain the highest extraction yield were determined as follows: solvent to material ratio 10 mL/g, extraction time 153 s and microwave power 322 W. Under the optimal extraction conditions, it can be included that the experimental extraction yield is (2.67± 0.06)%, which is close to the predicted extraction yield 2.64% attained by using regression model.

3Conclusions

Box-Behnken design was effective for estimating the effects of solvent to material ratio, extraction time and microwave power on the extraction yield of volatile oil from Fructus Amomi Rotundus. The linear term of extraction time and microwave power and the quadratic terms of solvent to material ratio, extraction time and microwave power had highly significant effect on the extraction yield. The optimal predicted extraction yield 2.64% was obtained, when the optimal conditions was solvent to material ratio 10 mL/g, extraction time 153 s and microwave power 322 W. Under the optimal conditions, the experimental extraction yield (2.67%) agreed closely with the predicted extraction yield.

[1]Committee of National Pharmacopoeia. The pharmacopoeia of the People's Republic of China[M]. Beijing: Chemical Industry Press, 2005: 53.

[2]LUCCHESI M E, CHEMAT F, SMADJA J. Solvent-free microwave extraction of essential oil from aromatic herbs: comparison with conventional hydro-distillation[J]. Journal of Chromatography A, 2004, 1043 (2): 323-327.

[3]GAO Shan, HAN Wei, DENG Xiu. Study of the mechanism of microwave-assisted extraction of Mahoniabealei (Fort.) leaves and Chrysanthemum morifolium (Ramat.) petals[J]. Flavour and Fragrance Journal, 2005, 19(3): 244-250.

[4]YOUN Y S, MING Y K, YUAN S C. Microwave-assisted extraction of ginsenosides from ginseng root[J]. Microchemical Journal, 2003, 74(2): 131-139.

[5]GONG S Z, CHENG J, YANG Z R. Microwave-assisted extraction of isoflavones from Belamcanda chinensis[J]. Chinese Journal of Chemical Engineering, 2005, 13(4): 556-559.

[6]XIAO Weihua, HAN Lujia, SHI Bo. Microwave-assisted extraction of flavonoids from Radix Astragali[J]. Separation and Purification Technology, 2008, 62(3): 614-618.

[7]GIRIJA R, VILAS G G. Microwave-assisted extraction of piperine from Piper nigrum[J]. Industrial & Engineering Chemistry Research, 2002, 41(10): 2521-2528.

[8]PAN Xuejun, LIU Huizhou, JIA Guanghe, et al. Microwave-assisted extraction of glycyrrhizic acid from licorice root[J]. Biochemical Engineering Journal, 2000, 5(3): 173-177.

[9]PAN Xuejun, NIU Guoguang, LIU Huizhou, et al. Comparison of microwave-assisted extraction and conventional extraction techniques for the extraction of tanshinones from Salvia miltiorrhiza Bunge[J]. Biochemical Engineering Journal, 2002, 12(1): 71-77.

[10]INCORVIA M M J, IANNUCCI B W A, DENSON C L. Microwaveassisted extraction of taxanes from Taxus biomass[J]. Journal of Agricultural and Food Chemistry, 1997, 45(12): 4691-4696.

[11]RUAN Zheng, ZHOU Quan-cheng, DENG Ze-yuan, et al. Study on optimization of extraction conditions of Platycodon grandiflorum A. DC polysaccharide using response surface methodology[J]. Food Science, 2008, 29(12): 283-287.

[12]XU Wentao, ZHANG Fangfang, HUANG Kunlun, et al. Application of response surface methodology for extraction optimization of water-soluble polysaccharides from Pteridium aquilinum[J]. Food science, 2008, 29 (7): 122-126.

[13]HAO Jinyu, HAN Wei, HUANG S D. Microwave-assisted extraction of artemisinin from Artemisia annua L.[J]. Separation and Purification Technology, 2002, 28(3): 191-196.

TS224.4

A

1002-6630(2011)08-0133-05

2010-07-22

徐州市科技發展基金計劃項目(XF10C003)

李超(1978—),男,講師,博士,主要從事天然產物化學及食品加工研究。E-mail:chaoge002@163.com